![]()

Utilizing Color Carbon Black in Inks: A Comprehensive Guide

Color carbon black, a versatile pigment, plays a crucial role in the formulation of inks across various applications, including printing and writing materials. This guide serves to elucidate the methods and considerations for effectively incorporating color carbon black into ink formulations.

Utilizing Color Carbon Black in Inks: A Comprehensive Guide

Color carbon black, a versatile pigment, plays a crucial role in the formulation of inks across various applications, including printing and writing materials. This guide serves to elucidate the methods and considerations for effectively incorporating color carbon black into ink formulations.

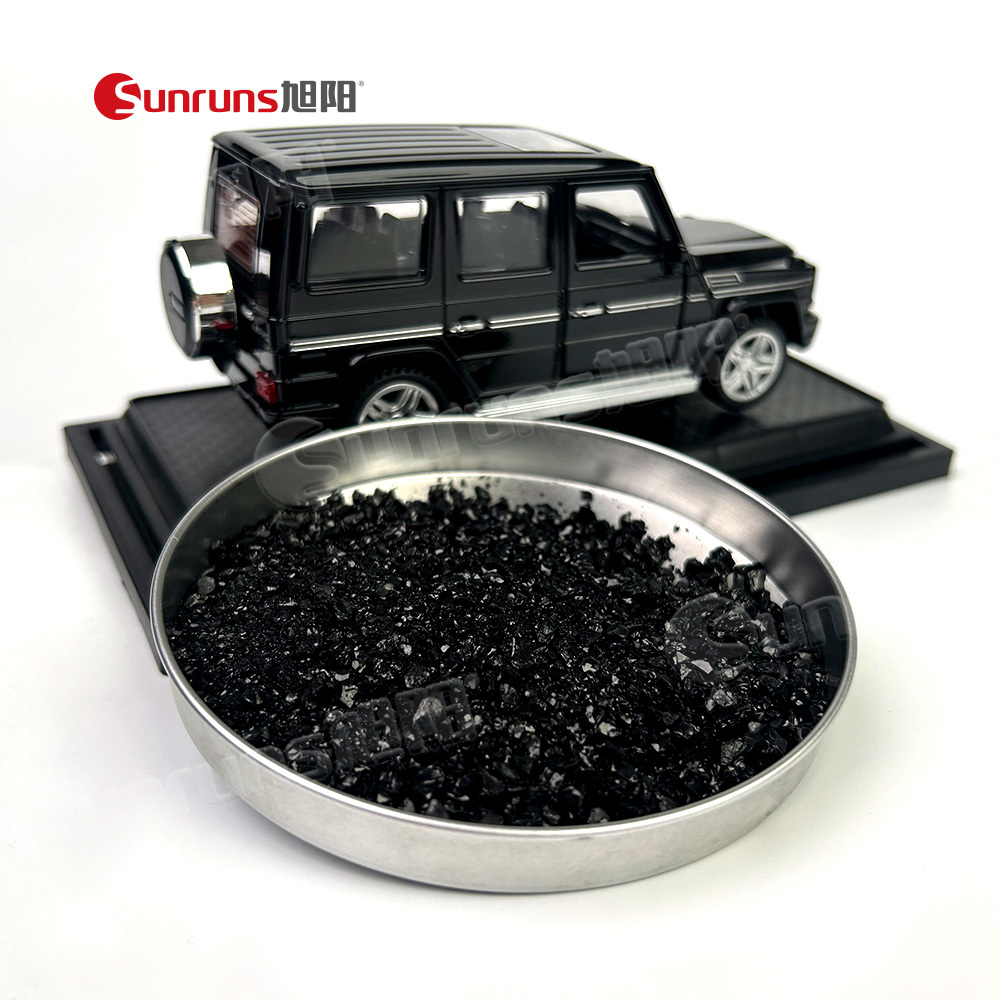

Understanding Color Carbon Black

Color carbon black is a finely dispersed, high-performance black pigment characterized by its exceptional tinting strength, stability, and opacity. Its unique properties make it an ideal choice for achieving deep blacks and enhancing color depth in inks.

Formulation Considerations

Particle Size and Distribution: The efficacy of color carbon black in inks is significantly influenced by its particle size. A finer particle size yields a more intense color while ensuring better dispersion. Careful selection and control of particle size, along with a well-distributed mixture, are vital for achieving uniform color and preventing clumping.

Compatibility with Other Ingredients: Prior to formulation, it is imperative to assess the compatibility of color carbon black with other components of the ink, such as resins, solvents, and additives. Conducting compatibility tests will aid in identifying potential interactions that may affect overall performance.

Dispersion Techniques: Effective dispersion of color carbon black is critical for optimal ink performance. Methods such as high-shear mixing, bead milling, or attrition milling may be employed to achieve a homogeneous mixture. The goal is to break down agglomerates and ensure that the pigment is evenly distributed throughout the ink.

Application Specifics

Type of Ink: Color carbon black can be utilized in various types of inks, including water-based, solvent-based, and UV-curable inks. The formulation process may include varying the ratio of color carbon black depending on the type of ink and its intended use.

Testing and Quality Control: Rigorous testing is essential to ensure that the ink meets desired standards of color strength, lightfastness, and stability. Quality control measures such as spectrophotometric analysis can provide invaluable insights into the consistency and quality of the final product.

Conclusion

Incorporating color carbon black into ink formulations requires meticulous attention to particle size, compatibility, and dispersion techniques. By adhering to these guidelines and conducting thorough testing, manufacturers can harness the benefits of color carbon black to produce high-quality inks with rich, intense colors. The strategic use of this pigment not only enhances aesthetic appeal but also elevates the overall performance of ink products in the market.