![]()

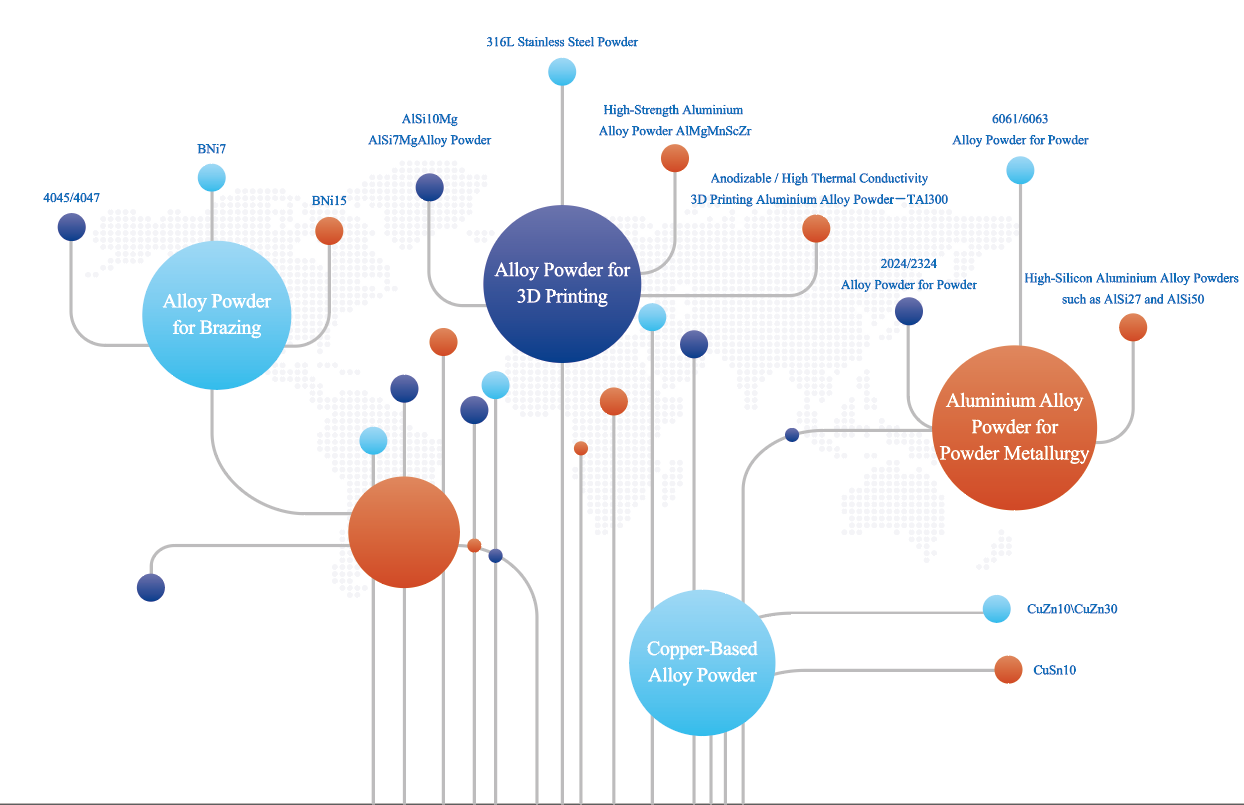

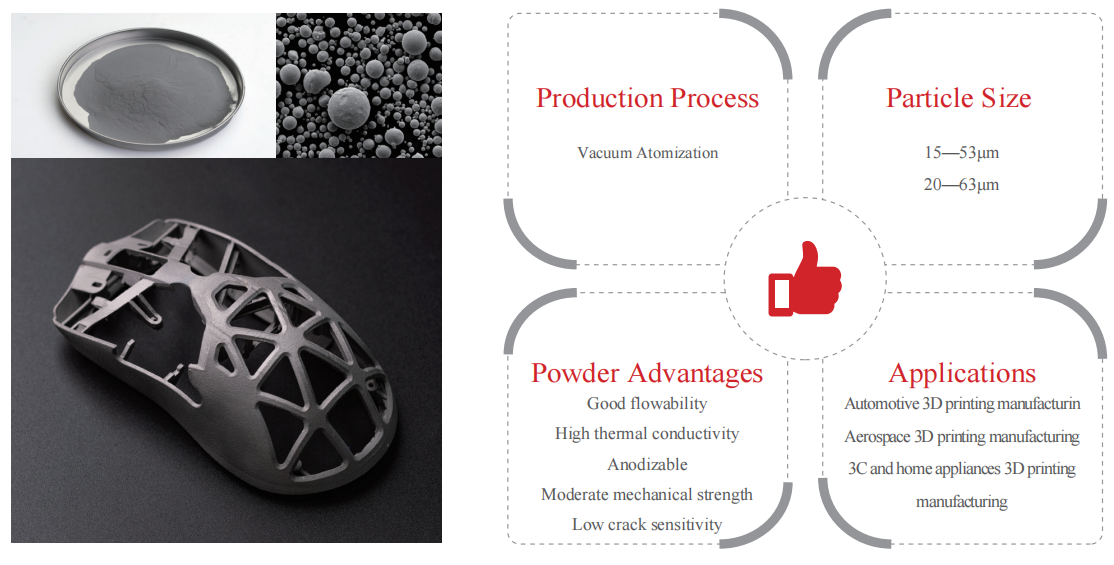

Alloy Powder For 3d Printing

Key word:Alloy Powder

Category:Alloy Powder For 3d Printing

Category: Alloy Powder For 3d Printing

Details

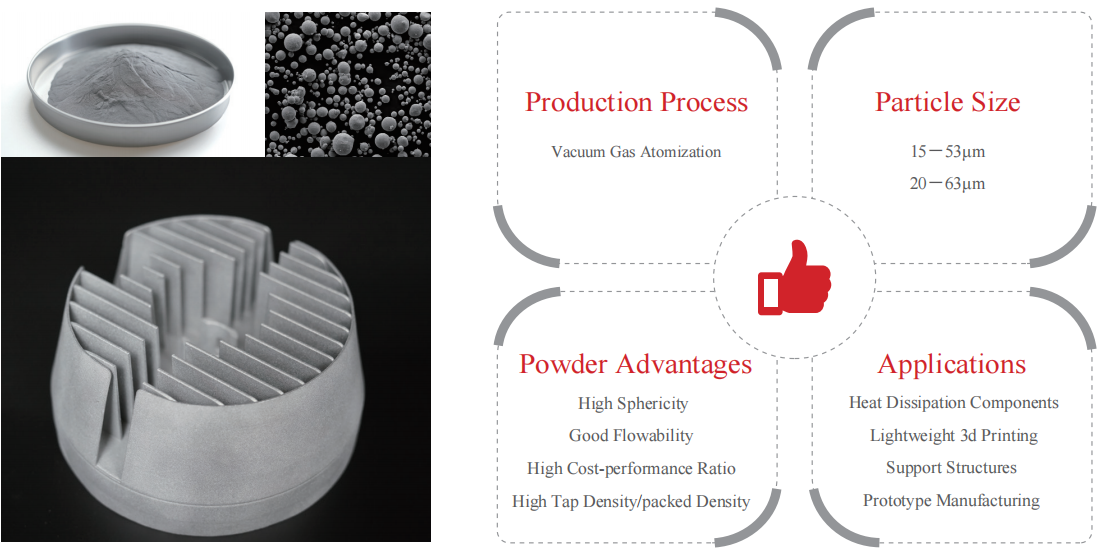

AlSi10Mg/AlSi10Mg Chemical Composition

| Name | Item | Chemical Composition | ||||||||||

| Al | Si | Mg | Fe | Cu | Mn | Ni | Zn | Ti | Pb | Sn | ||

| AlSi10Mg Content(wt%) |

Specification Range | Bal. | 9.0-11.0 | 0.20-0.45 | 0.55 | 0.05 | 0.45 | 0.05 | 0.10 | 0.15 | 0.05 | 0.05 |

| Test Results | . | 10.02 | 0.36 | 0.056 | <0.01 | <0.01 | <0.01 | <0.01 | <0.01 | <0.03 | <0.03 | |

| AISi7Mg Content(wt%) |

Specification Range | Bal. | 65-75 | 0.45-0.75 | 0.20 | 0.10 | 0.10 | 0.05 | 0.10 | 0.08-0.25 | 0.05 | 0.05 |

| Test Results | · | 7.15 | 0.56 | 0.08 | <0.01 | <0.01 | <0.01 | 0.011 | 0.16 | <0.03 | <0.03 | |

Product Performance Comparison

| Name | Specification | Particle Size(μm) | Liquidity (s/50g) |

Bulk Density (g/cm³) |

Tapped Density (g/cm³) |

Oxygen Content (ppm) |

Mechanical Properties Of Powder-printed Parts After Annealing |

||||

| D10 | D50 | D90 | Yield Strength Mpa |

Tensile Strength Mpa |

Strain at Break % |

||||||

| AlSi10Mg | 20-63 | 24.12 | 42.08 | 67.82 | 90 | 1.54 | 1.73 | 325 | 200±20 | 300±20 | 20±2 |

| AlSi7Mg | 20-63 | 23.98 | 43.04 | 67.71 | 93 | 1.44 | 1.64 | 516 | ≥200 | ≥300 | 13±2 |

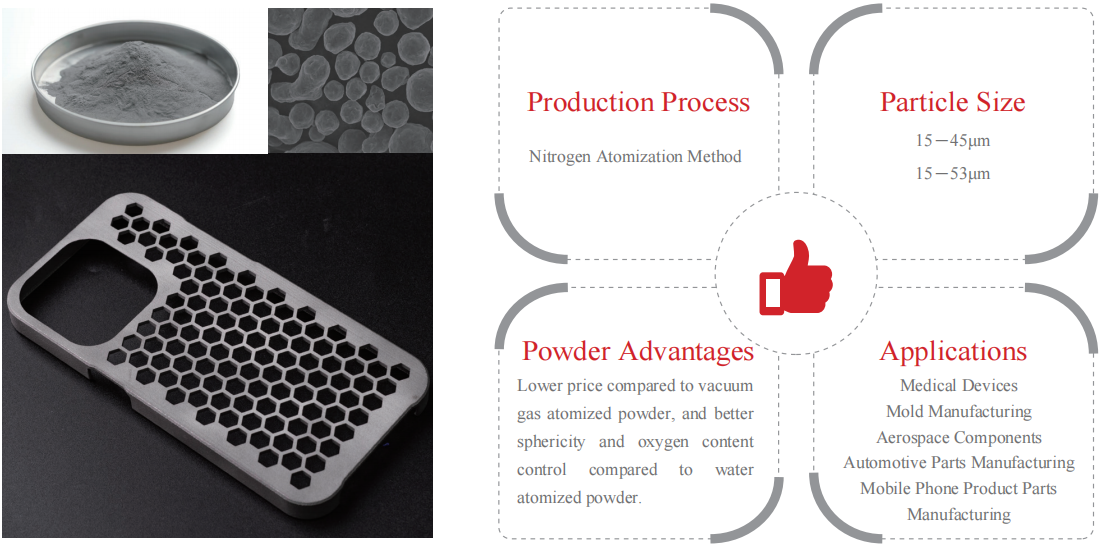

316L Stainless Steel Powder

Chemical Composition

|

Element Content

|

C | Cr | Ni | Mo | Mn | Si | P | S | Fe |

|

Content

|

≤0.03%

|

16 – 18%

|

10-14% | 2-3% |

≤2%

|

≤1%

|

≤0.045%

|

≤0.045%

|

Allowance

|

Printing Performance

| Product Name | Particle Size | Yield Strength | Tensile Strength | Elongation |

| 316L | 15-53μm | 200±20 | 500±20 | ≥35 |

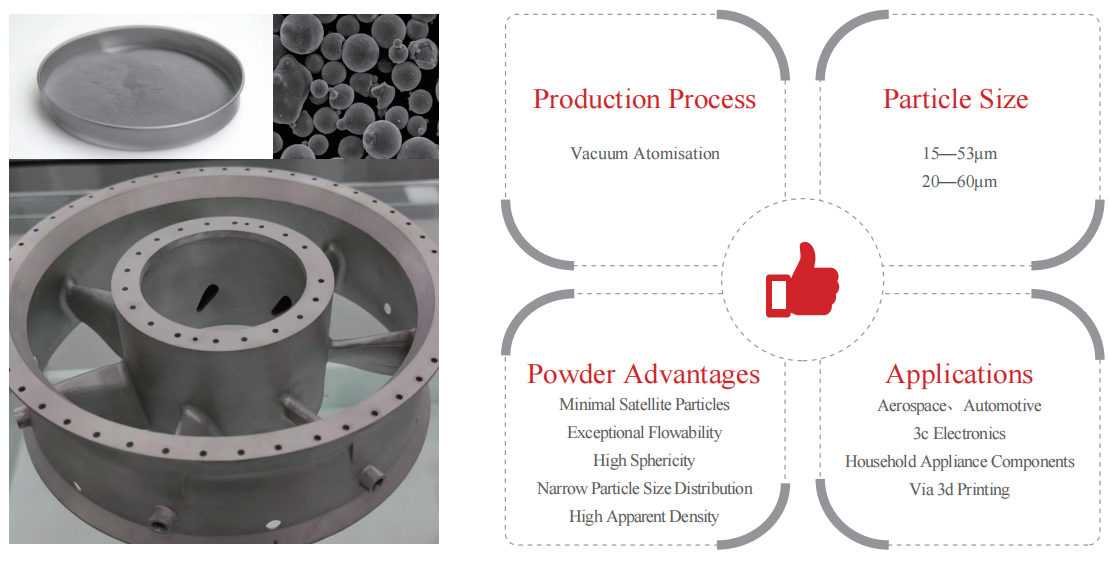

3D Printing Aluminium Alloy Powder—AM6013

Product Performance Comparison

| Name | Particle Size(μm) | Flowability(s/50g) | Yield Strength Mpa | Tensile Strength Mpa | Elongation% |

| AM6013 | 20-63 | 100±5 | 450±20 | 350±20 | 15-20 |

Anodizable / High Thermal Conductivity 3d Printed Aluminium Alloy Powder—TAL300

Product Printing Performance

| Name | Yield Strength(Mpa) | Tensile Strength(MPa) | Elongation(%) | |||

| Condition | As-printed | Heat-treated | As-printed | Heat-treated | As-printed | Heat-treated |

| Performance | ≥200 | ≥230 | ≥250 | ≥280 | ≥8 | ≥10 |

Thermal Conductivity

| Serial No. | Temperature(℃) | Thermal conductivity (W/(m.K)) |

| 1 | 25 | 225 |

| 100 | 226 | |

| 2 | 25 | 200 |

| 100 | 210 |

Related products

Online message

Please fill out the form below and we will contact you as soon as possible.