![]()

Порошок цинковых хлопьев

Key word:Zinc powder Dacromet coating Anti-corrosion

Category:Zinc Flake Powder

Аксессуары:

Подробности

Введение продукта

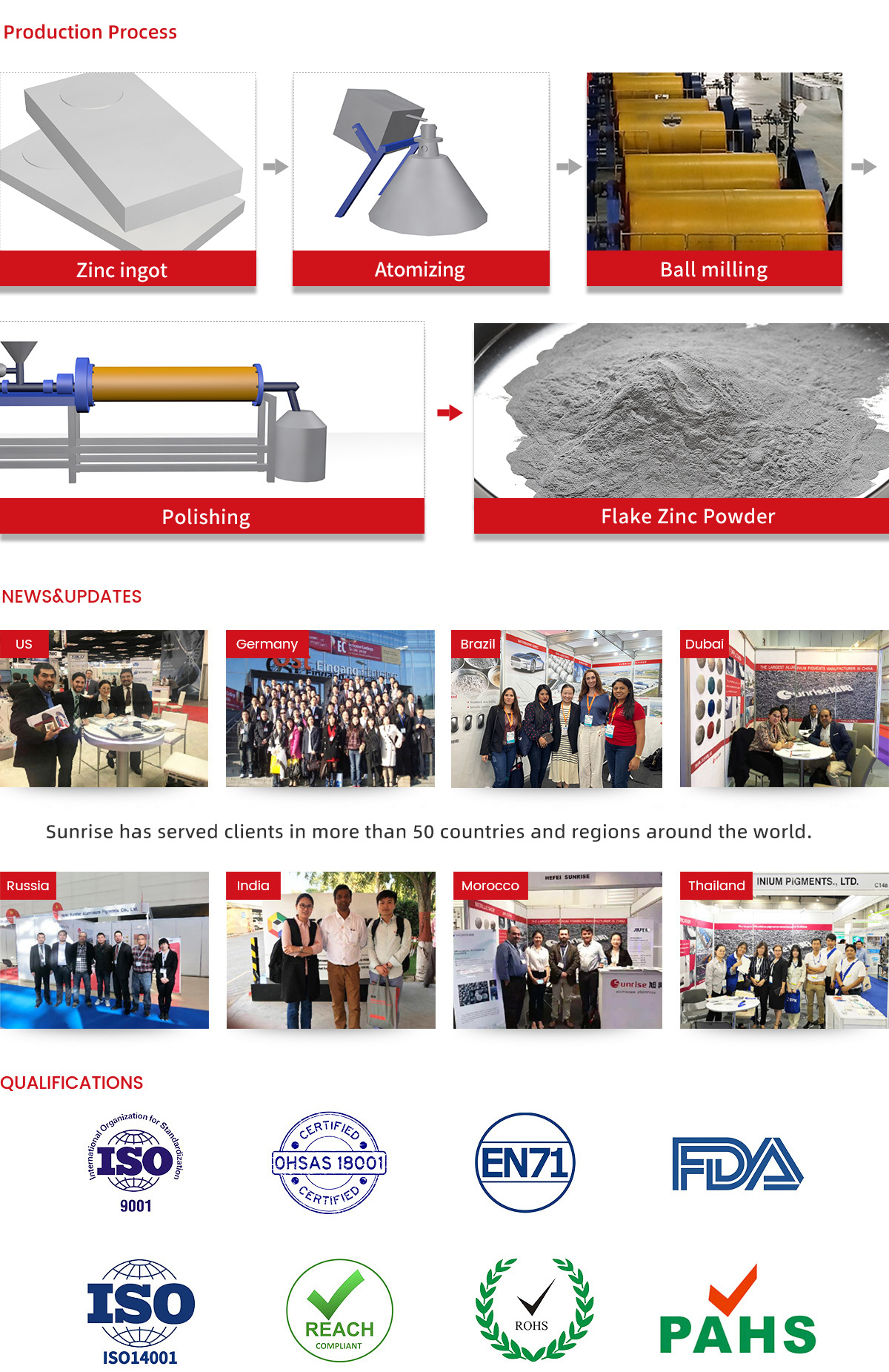

Zinc flake powder is made from spherical zinc powder by dry ball milling with lubricants. Zinc flake powder has stronger covering, floating and shielding properties as well as better metallic luster than spherical zinc powder. Thus it is widely used in zinc-rich anticorrosive coatings and coating technologies such as Dacromet and Geomet for marine, automobile parts, pylons, guardrails etc.

PRODUCT GRADES

| Класс | D50 (мкм) | Screen Analysis 150 mesh | Non-volatile content (%) | Bulk density (g/cm³) | Hiding powder (cm²/g) |

| X720 | 20±2 | <2% | >98% | 0.9±0.1 | >4500 |

| X715 | 15±1 | <2% | >98% | 0.8±0.1 | >5000 |

| X713 | 13±1 | <1% | >98% | 0.6±0.1 | >5000 |

| X705 | 5±1 | <1% | >98% | 0.4±0.1 | >6000 |

CHEMICAL PROPERTIES AND CHARACTERISTICS

1. Electrochemistry aspects:it can protect iron from corrision as Zinc is more active than iron and will react into solution in the

dielectric chemical reaction.

2. Sealing: due to the corrosive reactants of zinc powder, ZnCO3, Zn (OH)2 will deposited between the zinc powder particles and

fill the gaps between the pigments. It’s also non-conducting, thus playing a closed role in the coating.

3. Radiation: due to scale-like zinc powder parrelled on the surface of the coating film, they overlap and interlaced each others

which greatly decrease the chance of water and corrosive media penetrate through the coating, thus improving the corrosion

resistance of the coating

REMARKS:The flake structure has a significantly larger specific surface area than the spherical structure. Correspondingly, it’s more appopriate to use a higher content of binder and a lower pigment volume concentration (PVC) in the coating formulation to facilitate the adjustment of the coating properties to the respective field of application.

Приложения

Онлайн сообщение

Пожалуйста, заполните форму ниже, и мы свяжемся с вами как можно скорее.